A PCB is a printed circuit board. It is an imperative electronic constituent, an assistant for electronic mechanisms and a hauler for electrical relations among electronic components. Since it is created by printing a projected image onto a substrate, it is called a “printed” circuit board. It is usually made of copper coated with epoxy sap/glass. PCBs usually use multiple layers, with 4 and 6 being the most commonly used, depending on the number of signals required.

Finally, what is PCBA?

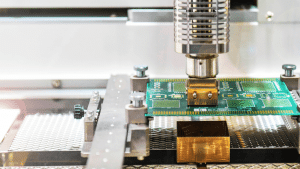

PCBA stands for the assembly of the printed circuit board and is connected to the location of the parts on the uncovered board or PCB. Electrons are collected from the circuit board and placed inside. PCBA company is a limited package; it is equipped with each main part and is ready to be sent for a good reason.

Components placed on a PCB can include capacitors, inductors, resistors, diodes, triodes, modules, BGAs and many others. A PCBA is a finished electronic assembly, while a PCB is an exposed electronic device.

What is a PCB?

PCB is the foundation of today’s electronics. They support and appropriately use electronic communication tools. The insulation is used, such as fibreglass or epoxy composite, and has conductive ways that connect the different parts of the board. These channels are printed or placed on the board as shown by the customized PCB layout. PCB type

The main types of PCBs include:

- Monolayer PCB is the simplest type of PCB and consists of a single layer of conductors and an insulating layer. PCB parts are kept separate by silkscreen printing.

- Two-layer PCBs have a material layer on the top and bottom of the board, giving them flexibility and a lower size than single-layer PCBs.

- PCBs are multi-layered multi-layered conductors and are used in other complex applications.

Other types of PCBs include flexible PCBs, non-flexible PCBs, and non-flexible PCBs.

Uses

The material used for PCB is usually fibreglass, epoxy composite, or other coating material. The conductors on one or both sides of the shaft are usually copper. Copper is also used to make printed circuits, which are placed or pressed on a piece of paper according to the design. Application

PCBs are used in many electronic applications, including consumer hardware, large equipment, mechanical engineering, auto parts, and medical equipment.

How Do PCBA and PCB Connect with One other?

PCB and PCBA are the aftereffects of two distinct strides of a similar and huge interaction. A PCB is a clean circuit board without digital parts connected, while a PCBA is a finished amassing that consists of each one of the parts expected for the board to paint depending on the state of affairs for the right application. A PCB isn’t always utilitarian, the same time as a PCBA is suited to be utilized in a digital gadget.

Fabricating a clean board is an extra truthful cycle than growing a completed PCBA because of the exclusive parts and cycles engaged with PCB gathering. It likewise charges more to deliver a PCBA than a clean PCB. In any case, the 2 tiers are essential to make a finished board. You cannot make a PCBA without a PCB. PCB generating is the maximum important section simultaneously, and PCBA fabricating expands upon that initial step.